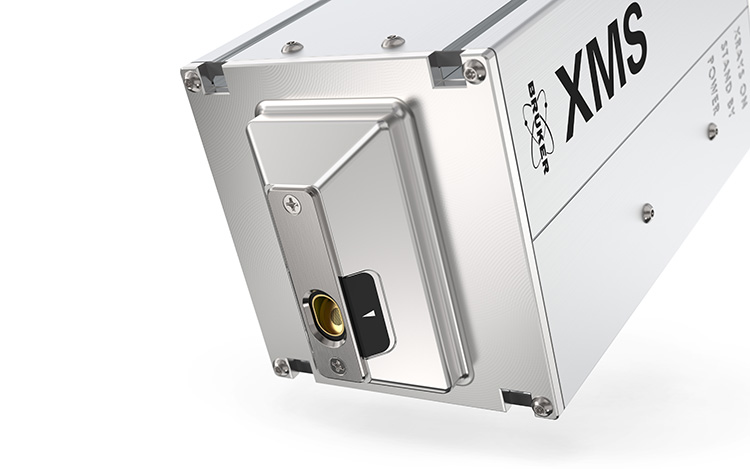

Brand:Bruker

Model:XMS

The XMS is a compact and rugged X-ray fluorescence measurement head designed specifically for industrial applications. Elemental composition analysis is increasingly required in many applications such as in the extraction of natural resources (minerals, metals, oil and gas), raw material transformation and manufacturing (metal alloys, glass, rubber), and metal and waste recycling.

The system’s fast data collection and analysis allows manufacturers and service providers to set up process control routines, pass/fail grade tests, and to optimize their production and quality yield.

Such a wide range of applications requires extremely versatile instrumentation with a robust design that can withstand industrial and harsh environments, a large element detection range, and reliable software to be integrated on the measurement line.

Integrating a state-of-the-art silicon drift detector with a Graphene window, the XMS allows for outstanding element detection performance. An optional helium purge is also available, enabling detection down to Na, which would be otherwise not possible.

The new detector technology together with the latest generation of a 50 kV X-ray tube with a Rh target, the XMS allows for FWHM @ Mn Ka < 145 eV up to 450,000 cps ensuring the best data in the shortest acquisition time.

Applications

Natural resources exploration:

Core logging is a fundamental step in geology, mining, oil and gas exploration. Cylindrical shaped rocks are drilled into earth with potential mineral deposits and the core’s elemental composition is accurately measured. The identification of even small traces of precious elements can drive important decisions for mining companies (e.g., to set up a new extraction site or not) or, for geologists, to give insights on the area’s geological history. The XMS, thanks to its rugged design and its universal API interface, is the ideal solution for the automation of core logging activities.

In-line process control:

In-line process and quality control represents the most effective approach for real-time performance of the production line and to take immediate corrective actions, maximize production yield and minimize operative costs. The XMS is built to be easily integrated onto conveyor belt systems for in-line and on-line stationary control.

Application examples are the measurement of the correct metal concentration mix before melting takes place inside a furnace or the quality control of metal alloys.

Tel:86-021-37018108

Fax:86-021-57656381

Email:info@boyuesh.com

Address:Room 301, 28 Songjiang Hi-tech park, 518 Xinzhuan Road, Songjiang District, Shanghai